How to choose the right equipment for your farm and your sows? What are the advantages of having an electronic feeding system? What aspects of a feeding system should you prioritize? These are all valid questions to ask yourself when deciding to switch to electronic sow feeding.

This is where we come in! Zaxe has a team of professionals and experts in the field to advise and help you with your project. Whether it is for the retrofitting of an existing building or for a new one, our swine products are sure to satisfy you. We strive every day to develop innovative products to offer you the best of agricultural technology, in order to simplify your task and offer you unparalleled peace of mind.

One thing is certain: all electronic feeding systems serve the function of feeding sows. However, it is important to know the differences between the multiple feeding systems and related equipment available on the market. Since you are undoubtedly an experienced manager, it will be essential for you to be well informed to make the best choice in order to increase your productivity and have the best on investment.

When talking about innovation and technology, one of the things we mean is our electronic feeding system in gestation and farrowing. It is an automated and easy-to-use system that is sure to save you time, labor and money. Several options are available to you depending on your needs. Our service offer includes the Sow Feeding Station, the 3P Feeder, the Antenna in gestation and farrowing, a range of Bluetooth Tag Readers, Electronic Ear tags and let’s not forget our Bin Scales and Automatic Bin Valve. All controlled by the Maximus Solution. Besides being the most complete system on the market, it has been tested and proven to meet all your needs, even exceeding your expectations. It takes into account animal welfare as well as efficiency and precision, guaranteeing you high productivity. Be cautious! Some will tell you that you don’t need all of this to run your farm well, but know that only you can know what you need!

Did Your Sows Receive Their Feed Ration?

That is the question on every producer’s lips! How can you be sure that your sows have received their feed ration? To answer this, Zaxe offers you the 3P Feeder, an integral part of our feeding system, to feed your sows with great precision. What sets it apart from other feeders on the market: its unmatched characteristic! In fact, Zaxe has developed an effective feature that warns you if your sows have received their feed ration or not. We call it the Bobble head; a unique and patented smart feed flow sensor. With this innovative tool, you now have the certainty that your sows have received their daily feed ration, or be notified to be able to rectify the situation as quickly as possible.

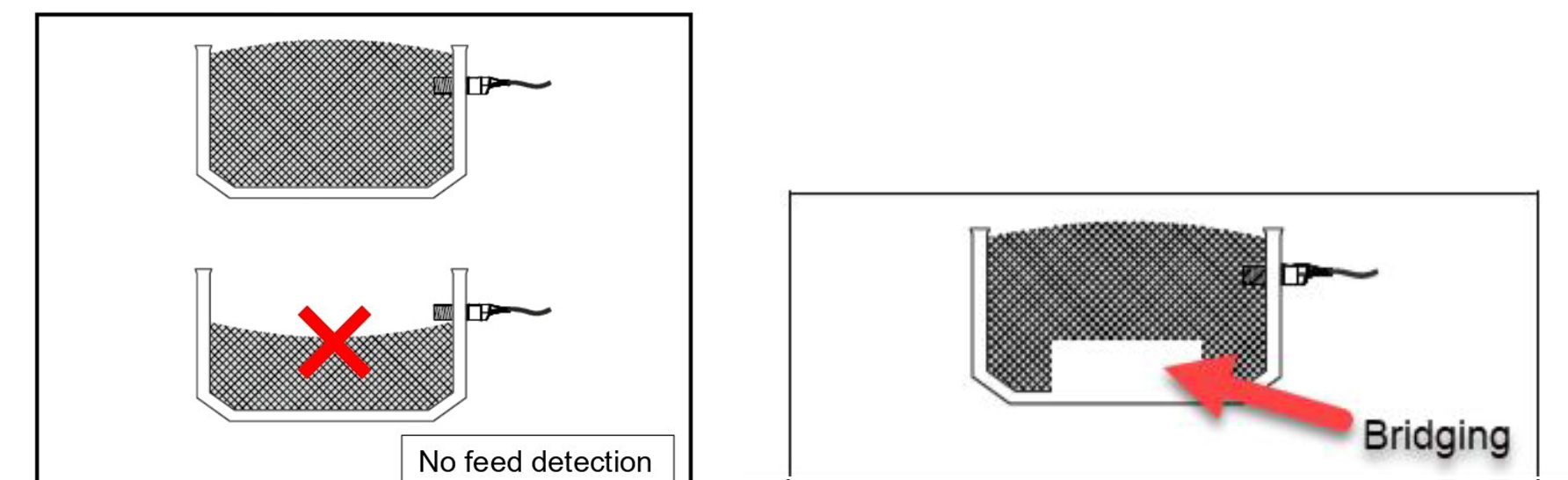

Some will tell you that a feed sensor (prox switch) with a humidity sensor is enough to tell if your sows have been fed, but think again! In fact, this type of feature does not provide an accurate reading of the feed remaining in the bottle. It can simply indicate whether there is feed or not in the feeder, depending on where it is installed. The sensor also does not certify that the feed has been distributed, so cannot certify that the sow has in fact received her ration. The sensor does not read the last extraction point, where the feed falls from the feeder, although this is the primary function of the Zaxe Bobble head due to its location in the feeder. As a result, if there is bridging in the feeder, the sensor does not indicate where the problem is and does not recalibrate the amount of feed to redistribute to the sow for precision feeding. Finally, the feed sensor is an electrical element, therefore requires additional maintenance (breakage by lightning, wear and tear, overvoltage, etc.), while the Bobble head is a mechanical element easy and simple to maintain thanks to its concept. The two images below represent well the disadvantages of a prox switch in a feeder.

From Gestation to Farrowing in Seconds!

Transferring sows from gestation to farrowing is a task that can involve a risk of error and requires manpower. So, the question is: how to optimize everything? How to reduce labor and errors? Why ask employees, sometimes inexperienced, to act and make decisions that could harm your livestock and create huge financial losses?

This is now a thing of the past with the Zaxe Antennas! In gestation as in farrowing, our antennas allow you to coordinate the needs of your sows with your installations, when connect to the Maximus module. A simple electronic tag reading automatically transfers your sows’ data from gestation to farrowing. You have access to the sow’s feeding matric, its location assignment as well as its complete history in real time, without any manual entry required. This makes it easier to perform this task, but more importantly, it helps reduce errors that can affect your production.

Another way Zaxe makes it easier!

Single, Double, Triple or Quadruple… Which Station to Choose?

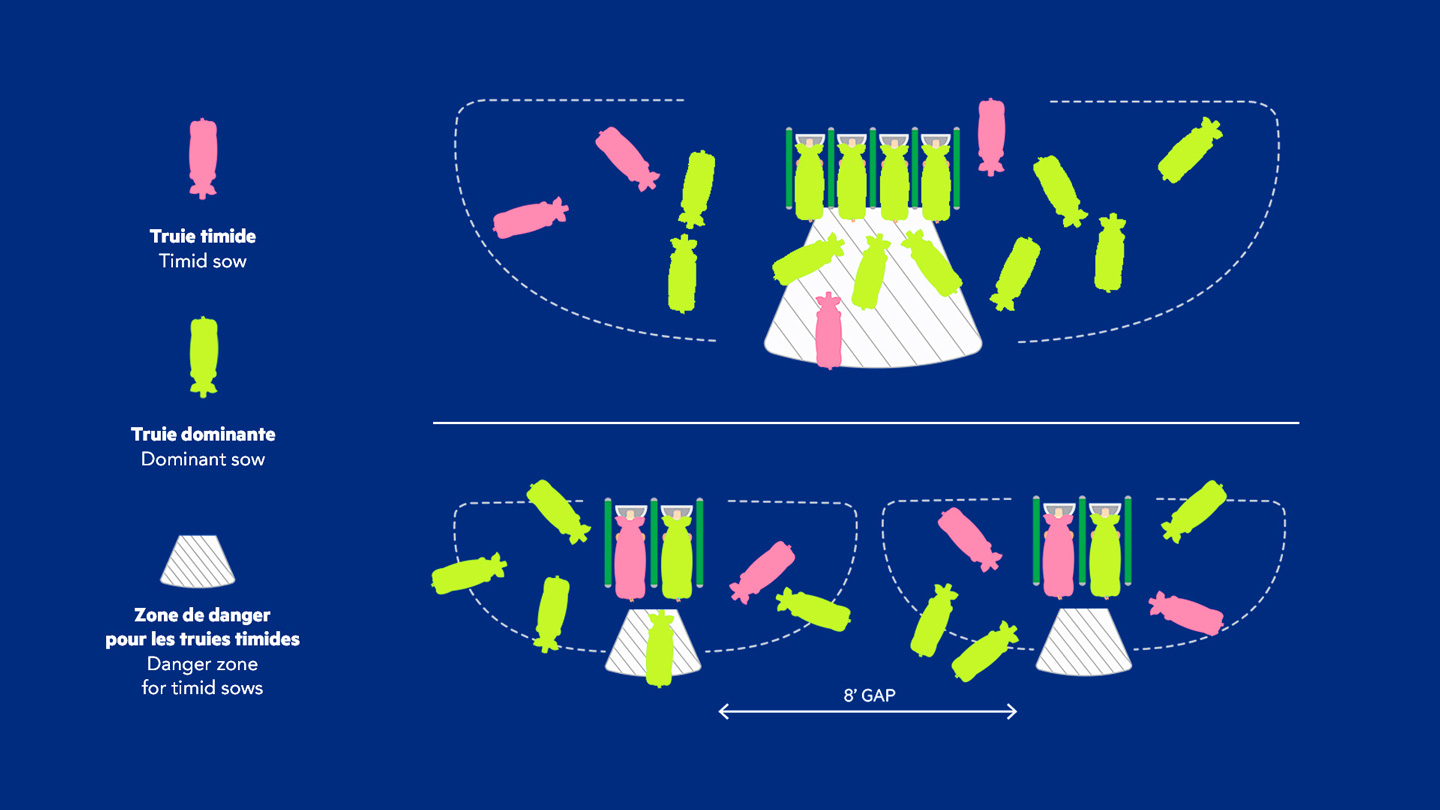

We cannot say it enough; all feeding systems are made to feed sows! However, there are some important criteria to consider when choosing your equipment. For example, which station size to choose in order to optimize production and ensure that all your sows are fed adequately (single, double, triple or quadruple)? Of course, each producer has their preferences. But there are advantages and disadvantages associated with your choice of feeding station. In a gestation pen, it is completely natural and normal for a hierarchy to form in the herd. Indeed, some sows will be more dominant and other more timid and more fearful. This can become a problem when it is time for them to feed in feeding stations. As a result, a more timid sow is less likely to feed properly if she is afraid of approaching dominant sows that may be in front of the stations, thus creating stress to the animal. This situation is therefore not optimal if we look at the “production” aspect of the herd. How do we solve this problem? Our swine production experts have studied this phenomenon for several years and have come to the following conclusion: prioritize double feeding stations! Many believe that a quadruple station is more productive than a double station because it can feed more sows at the same time. On the other hand, when we think about the hierarchy of the herd, we realize that this is not necessarily true. It is therefore more advantageous to have two distanced double feeding stations than a single, triple or quadruple station to optimize the feeding of your herd. In fact, the larger the station, the larger the “danger zone” in front of the station, and the less opportunity the timid sows will have to feed properly, as they will be afraid to enter. The pen layout example below demonstrates this very well.Let’s not forget that the Zaxe feeding stations can feed up to 20 sows per station. With that said, an optimized pen layout could very well be the key to success of your production!

What Does the Sow See?

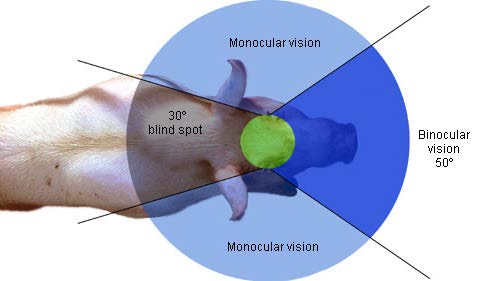

A sow’s vision is very different from ours. This is why it is important to take this into account when planning the layout of your gestation pens and making your choice of feeding station, to create a favorable environment for your animals.

All producers have the same goal: that their sows eat properly! It’s so easy to say, but not so easy to set up optimally. In fact, the competition between the sows is a big factor here. All sow herds have a hierarchy, whether it is visible or not, and this can create competition, fights and even mortality. We certainly want to eliminate this to a minimum to be as profitable as possible and to provide a calm terrain for sows. Some common behaviors can be noticed in a herd, such as the way a sow turns her head when sensing potential danger (a dominant sow watching a feeding station, for example). These behaviors and movements are due to the way sows view the environment around them. It is therefore important to properly plan your gestation pens, to void unnecessary competition between sows and reduce stress in the herd. The image below is a good representation of a sow’s vision.

Since they don’t have a binocular vision like humans, sows must develop appropriate behaviors and movements to detect dangers around them. Our feeding station is the right equipment for this situation. This is one of the main reasons that led us to develop a “western” style door over

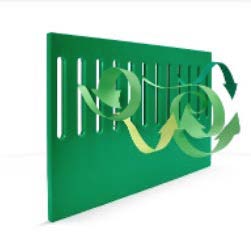

a tilted one. We also opted for a station with perforated Paneltim sides. For us, it is essential for the sow to be able to feed while being able to see her environment, as well as to feed without the possibility of being bitten. Several benefits are attached to it: it reduces stress, allows the sow to feed more quickly and decreases the training time of the gilts.

Create therefore a calm and favorable environment so that your sows can eat and rest properly!

Your animals at the heart of our products!

At Zaxe, we have animal welfare at heart. This is why we develop high-performance, meticulously assembled equipment from durable materials that are safe for your animals. This is our priority!

For example, our feeding station is, among other things, built with side panels made of Paneltim, a plastic specially designed for the agricultural sector. In fact, these panels are recognized as the most durable and robust used in farms around the world. Did you know that by choosing Paneltim in the color green, you are helping to protect the environment? In fact, green panels are made from recycled materials. In addition to these features, the panels used in the Zaxe Feeding Station are ventilated, that is, the sides of the station are openwork, thus ensuring the well-being of the sow while she is feeding creating a safe environment. Some models on the market do not offer this comfort and have a concept that can hamper more timid sows when it comes to feeding.

Zaxe also offers the use of the panels for resting areas and pen fences, providing sows with a protected place to rest. In addition, Paneltim panels have an anti-bacterial and sealed coating, making them easy to clean. This aspect therefore increases the biosecurity of your farm.

All of this contributes to the well-being of the sows at the farm, because happy and healthy sows should be your priority as much as ours!

From the Bin to the Feeding Tray!

A complete feeding system is nothing without the bins in which feed is stored for your animals. Products like the Zaxe Bin Scale and Automatic Bin Valve allow you to weigh your bins with great precision for better management of your feed inventory!

With the Zaxe Bin Scale, you are now able to weigh your bins properly to make sure that you always have enough feed for your animals. Know your feed inventory I real time and also coordinate your feed deliveries accordingly when connected to the Maximus intelligent controller. Producers are therefore able to have control over their feed inventory at all times and in real time. Tracking the feeding curve of animals and making sure their needs are met, thus detecting any abnormalities and diseases in your herd has never been so quick and easy.

For tandem bin layouts, it is also possible to combine your Bin Scale with our Automatic Bin Valve. This makes it possible to automatically switch from one bin to another when the predetermined low critical point (minimum level of feed in the bin) is reached. This gives you time to fill your main bin without worrying about running out of feed. In addition, these products eliminate the risks related to biosecurity caused by the comings and goings of employees and they save you time and labor.

Be alert and keep control over your feed inventory by knowing precisely your weekly consumption to better manage your production and your budgets. All this remotely and in real time!